top of page

Provided with concepts, my team was tasked with producing multiple one-off scenic builds for the 3- day draft haus event. Multiple props were to be reused for future events.

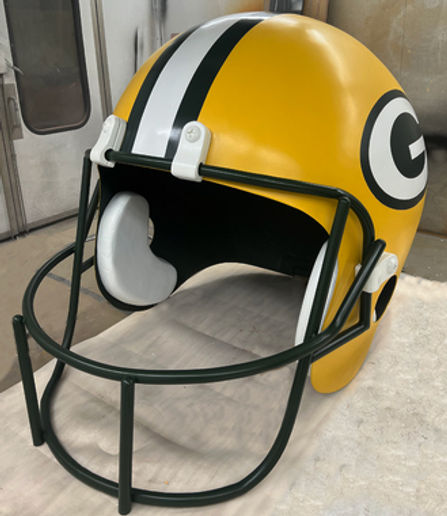

My contributions included the production design of a 5'x6' branded football helmet intended for the draft haus and future events.

Design considerations included:

-

Maintaining IP

-

Maintaining project budget

-

Build co-operation on sit

-

Typical wear and tear

-

Transportable/ lightweight Build

-

Quick production time

-

Clean and seamless finishes

The final design utilized a fiberglass shell for the helmet, and thin gauge steel tube for the helmet face mask.

Additional elements included:

-

Facemask Clips (3d-Printed, Molded, and Cast)

-

Cheek pads (CNC-milled, hardcoated foam).

Design Processes Included:

-

CAD Modeling (Rhino 3D

-

Master, Mold, and Assembly Design

-

Export for CNC Machining

-

Production Drawings for Fiberglass, Welding, Carpentry, and Fabrication builds.

DEFINE.

IDEATE.

DESIGN.

BUILD.

IDEATE.

DESIGN.

BUILD.

bottom of page